News

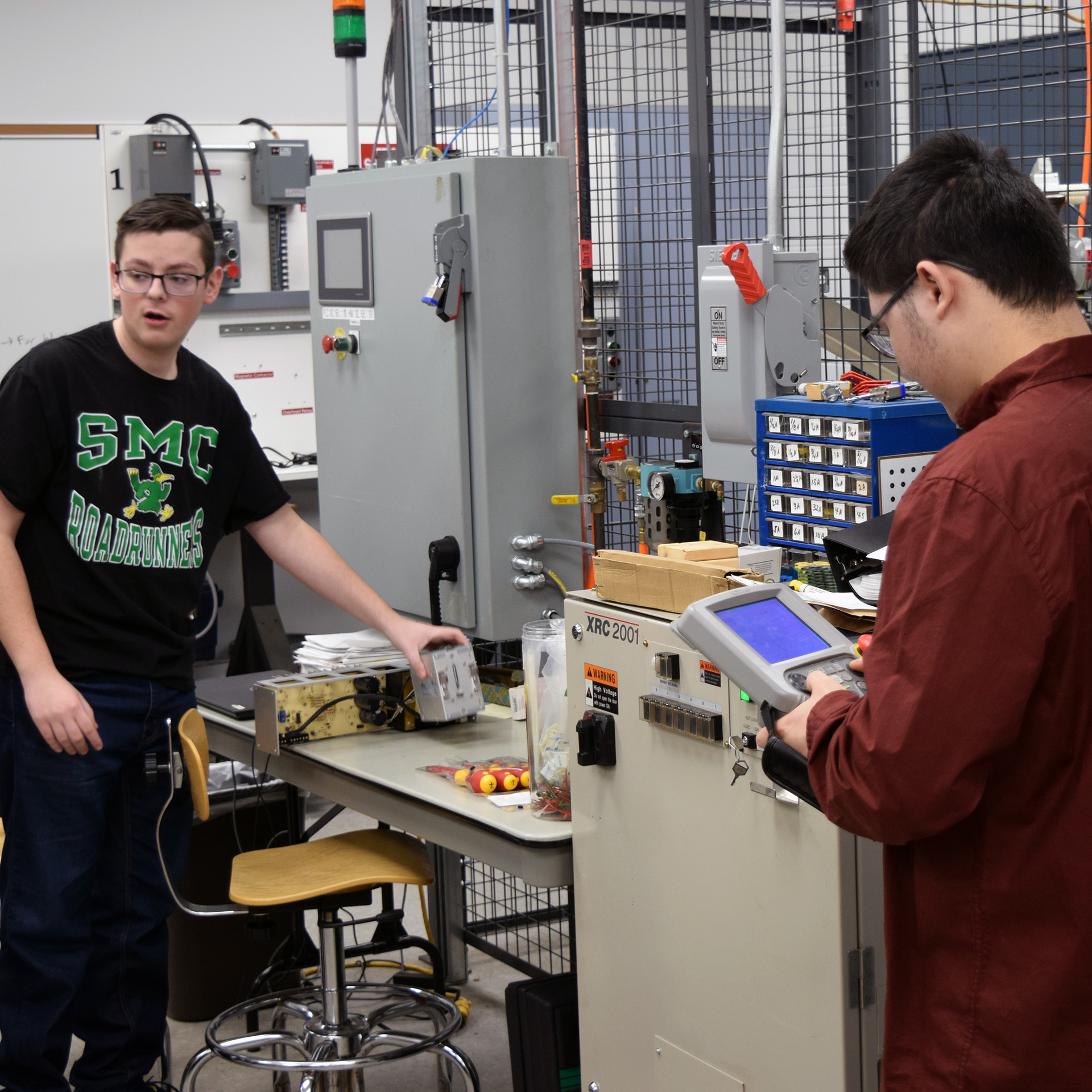

SMC Niles Campus Hosts 108 for Welding and Robotics Day

Published on February 26, 2024 - 3 p.m.

Eagle Technologies Manufacturing Manager Jay Bauer likens his Bridgman business to putting puzzle pieces together.

As he told 108 students from Cassopolis, Watervliet, Buchanan and the South Bend Career Academy attending Southwestern Michigan College’s Welding and Robotics Day Feb. 23 on the Niles campus, “You’re going to see robots, welders, electrical circuits and PLCs (Programmable Logic Controllers, industrial computers which control and monitor equipment based on programming),” Bauer said, “as a portion of something. We put all the pieces together to make a system. We are a service company that provides solutions for our customers. Manufacturers come to us with a part, and they need one of these every 3.5 seconds, and we need to check that it works and that the colors match.”

For example, Bauer showed a video featured on NBC’s Today Show that depicts equipment assembled for vertical farming.

“PLCs are brains,” Bauer said. “It makes decisions based on inputs it gets, issues outputs and takes action. A PLC common in everyday life is a traffic light, red in one direction and green in the other. If a pedestrian hits the crosswalk button, the PLC changes the traffic pattern to allow the person to cross safely.”

The video shows lettuce being planted in “towers” by robots.

“There are 127 plants on each side of the tower,” he said. “Everything is precisely measured. They can grow and pick lettuce every three days,” Bauer said. “You can get three pickings out of each plant. They can feed urban areas by producing natural, fresh foods in warehouses. We helped them with that solution. We are in electric vehicles, agriculture, heavy equipment, life sciences — contact lenses, pharmaceuticals, — pretty much anywhere someone is making something, we have a presence, with installations around the globe in China, Mexico, Canada and Europe.”

“There’s a travel element to what we do,” Bauer said. “We build it on our floor, then install it on the customer’s floor.”

“We’re an employer who uses SMC students,” Employee Relations Specialist Nancy Miller added. “You could attend classes here to learn the concepts of electronics, programming robots and building in general. We want you to know that attending college here and/or an apprenticeship through us helps bring everything full circle, applying the concepts at a job. If that seems intimidating, our teams are all small pieces of a larger puzzle. We’ve got individuals who are designing it in mechanical engineering, individuals who are building the frame of a machine or a robot, individuals who run the electrical or fluid power, the air or water supply to a machine. Then we’ve got someone who comes in and programs the robots. Those are all pieces of the puzzle that you can learn by coming to SMC. We took 12 SMC students last year.”

“We take pride in partnering with SMC,” Miller said. “When you do well in your classes, your instructors reach out to us and say, ‘We’ve got a good candidate for you.’ We offer apprenticeships in electrical, machine building, machinist and fluid power technician.”

Bauer said, “You’re constantly on the front edge of technology. A lot of machines we build assemble things that haven’t hit the market yet. People don’t know they exist yet. I installed an airbag igniter machine on a military base in the middle of China. There’s no other way I’d get an experience like that.”

Bauer joined Eagle in 2015 and has been in the industry for more than 30 years, going through an apprenticeship program himself. He since added a bachelor’s degree in organizational leadership through a tuition reimbursement program.

“All the education I have has been paid for by my employer, which is a huge advantage when it’s offered to you,” Bauer said. “Robots don’t eliminate jobs, they perform jobs that are unsafe and less desirable, creating technical jobs.”

Eagle employs some 300 people with three southwest Michigan locations, which Bauer called a “large small business. Our company supports a lot of local families and organizations. We’re very active in our community sponsoring soccer teams and the like because those are our kids and our folks coach those teams.”

,-wrestler-Vince-Arebalo.JPG)